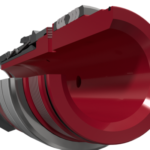

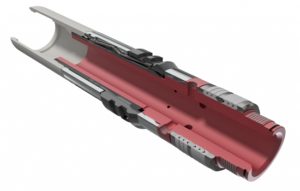

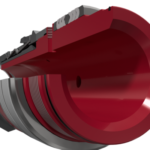

The keys of the P-R Lock Mandrel incorporate two 90° shoulders to locate in the profile whereas the P-RN Lock Mandrel keys are machined with 45° angles in order to allow the Lock to pass through profiles and rely solely on a No-Go shoulder for positive location; for this reason the P-RN Lock Mandrels are considered ‘Non-Selective’ and are typically run in single nipple tubing strings, or to set in the bottom nipple in a series of ‘Selective’ P-R Nipples. The ‘Selective’ P-R Lock Mandrel can be run in both a ‘Selective’ or a ‘Non-Selective’ position depending on the requirement to pass through Nipples of the same size.

It is necessary to consider the Well environment and conditions when discussing the pressure rating of the packing unit, PTP offer Lock Mandrels in appropriate sizes and models up to 10,000 psi.

The P-R & P-RN Lock Mandrels can be supplied in various Seal Material Configurations and materials to suit custom operational and environmental requirements.

An operator can place as many ‘Selective’ nipples with the same ID in the tubing string (without regard to a specific sequence) to provide more positions for setting and locking subsurface flow controls. PTP offers a large variety of seal stacks from our standard seal stack (Molyglass/HNBR) to other combination elastomeric/non-elastomeric. All PTP Lock Mandrels can be supplied in materials conforming to NACE standard MR-0175 for sulfide stress cracking with alternative materials available upon request. P-R & P-RN series Lock Mandrels are commonly used in heavy weight tubing strings.