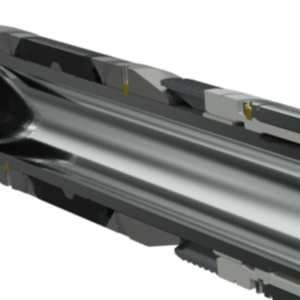

The ‘P-SAB’ Packer is run together with the ‘P-ALS’ Anchor Latch and a Plugging device below; this allows for a build-up of pressure in the tubing to set the Packer. Packers are designed with a left hand connection at the upper end of the Mandrel for the Anchor Latch to latch into, to attach the Packer to the tubing string. Setting requires no tubing manipulation, thereby eliminating problems brought about by spacing out of the tubing.

The Packer is designed with careful consideration to materials; particularly components which are exposed to the well fluids. All alloy materials within the Packer conform to NACE MR0175 and are suited for operation in H2S service. The Packer can be manufactured from special material configurations upon request.

The P-SAB Packer is designed to withstand pressure differentials up to 10,000 psi.

Solid construction with a field proven Element System, allowing for quicker run-in without fear of impact damage or premature setting.

The hydraulic setting mechanism makes the ‘P-SAB’ Packer ideal for use in high angle deviated wells, and virtually any other well conditions. The Packer utilizes a full circle, one piece opposing slip system supported by tapered cones set in opposition and a Packing Element System consisting of Bi-directional Slips to ensure reliable and permanent anchoring. The ‘P-SAB’ Packer is designed with Interlocked, expandable metal back-up rings that during setting will contact the casing and create a positive barrier to offer support against Packing Element extrusion.