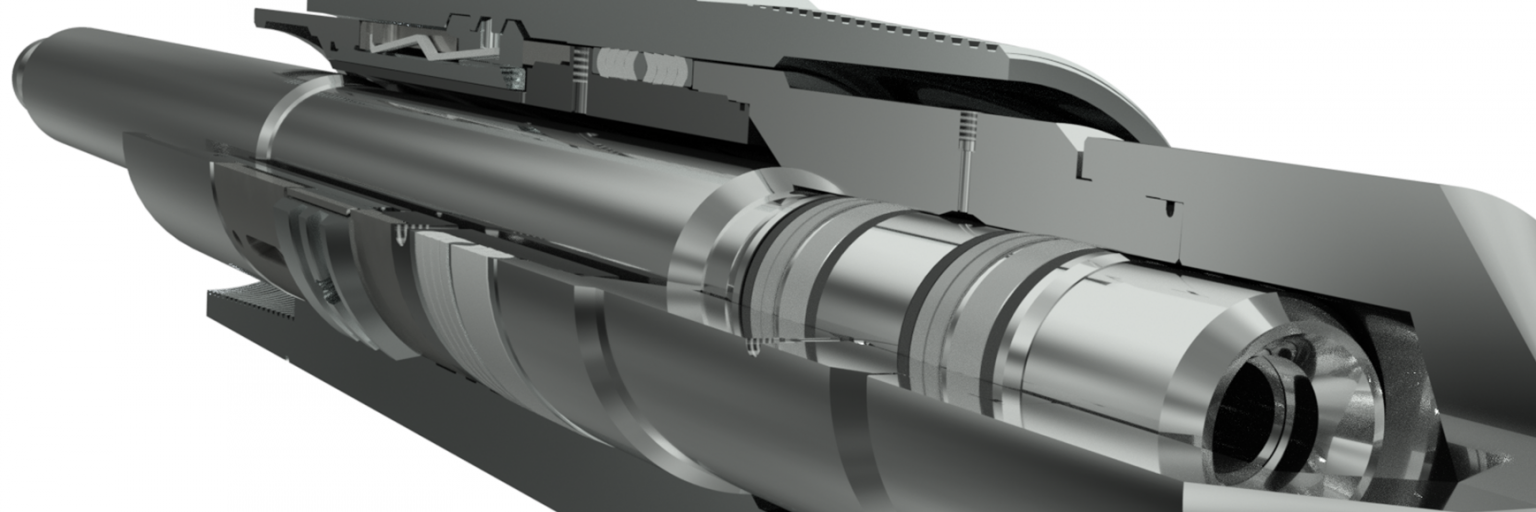

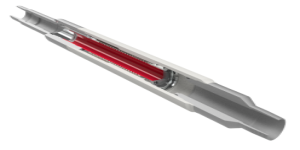

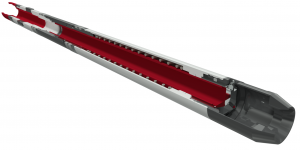

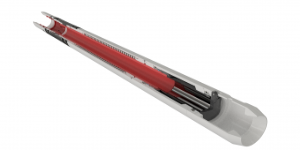

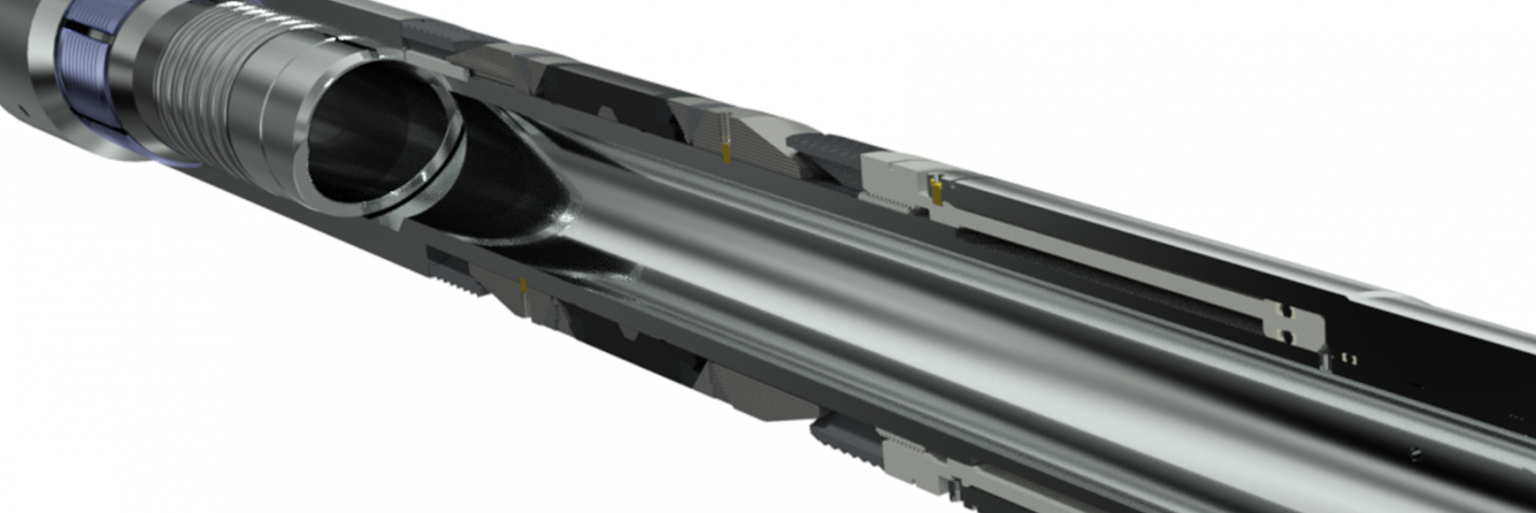

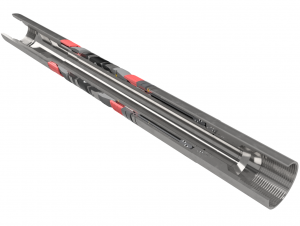

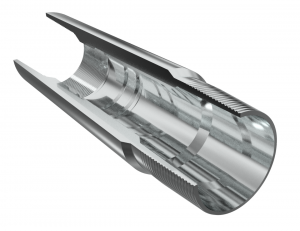

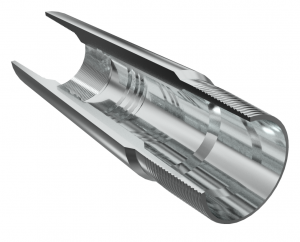

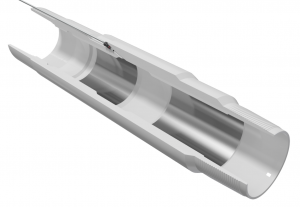

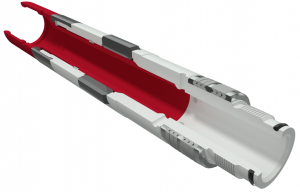

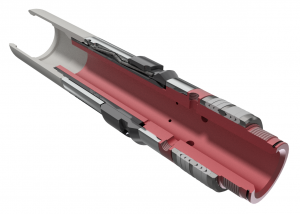

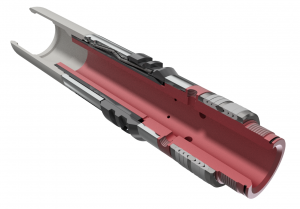

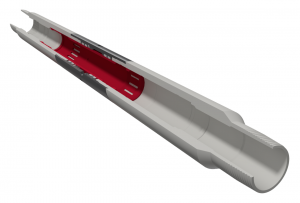

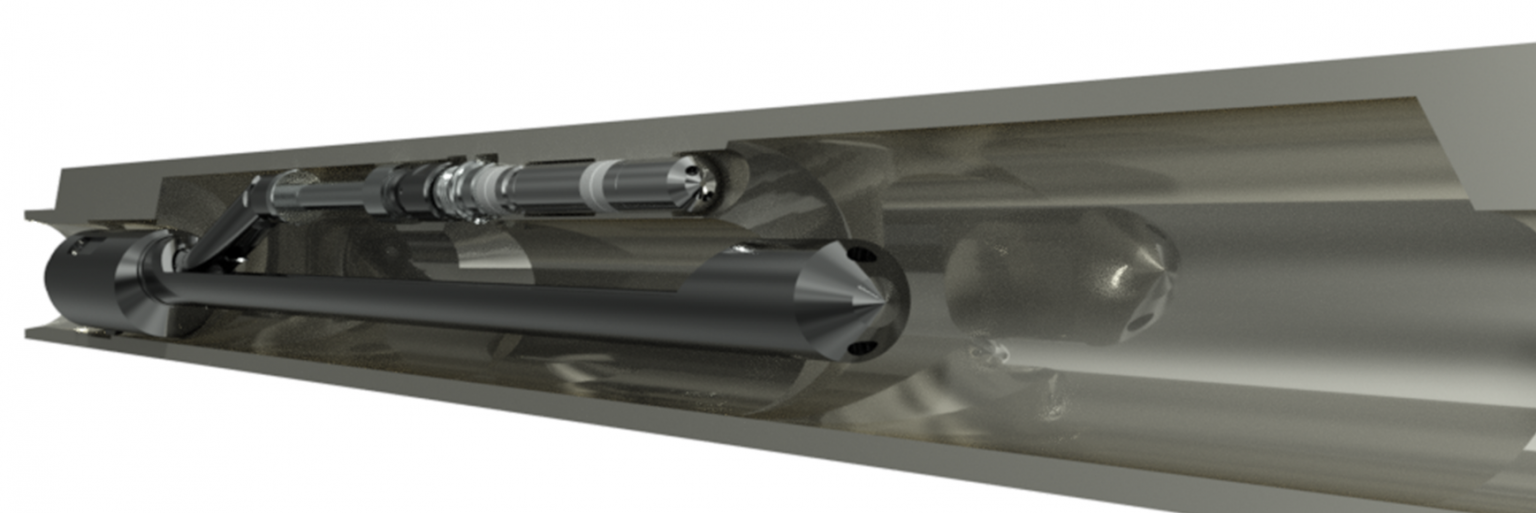

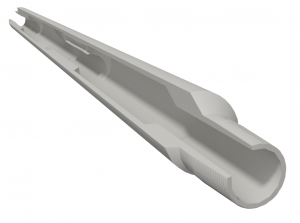

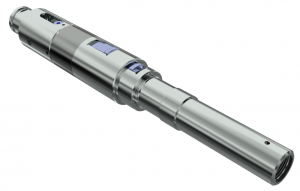

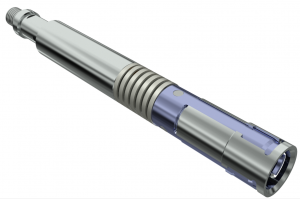

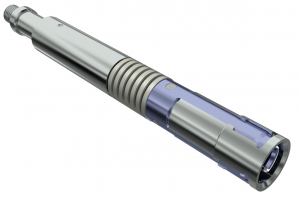

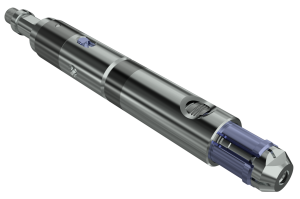

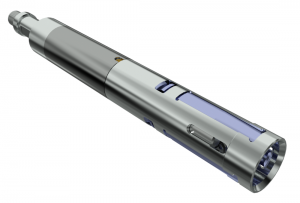

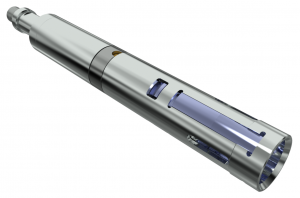

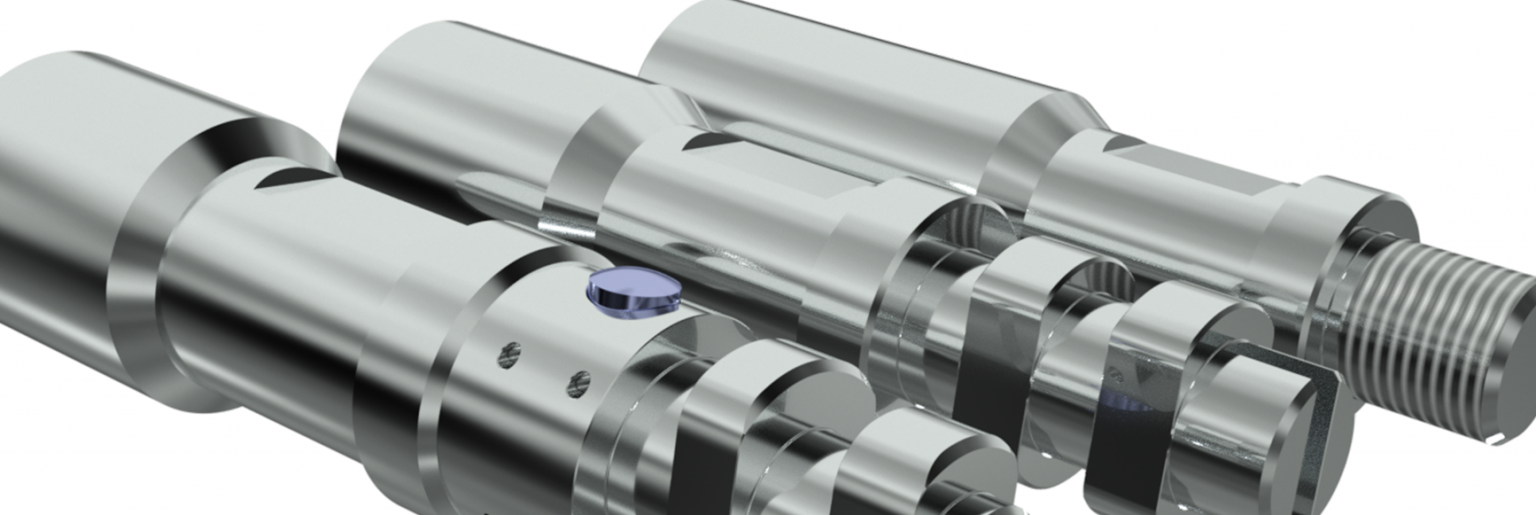

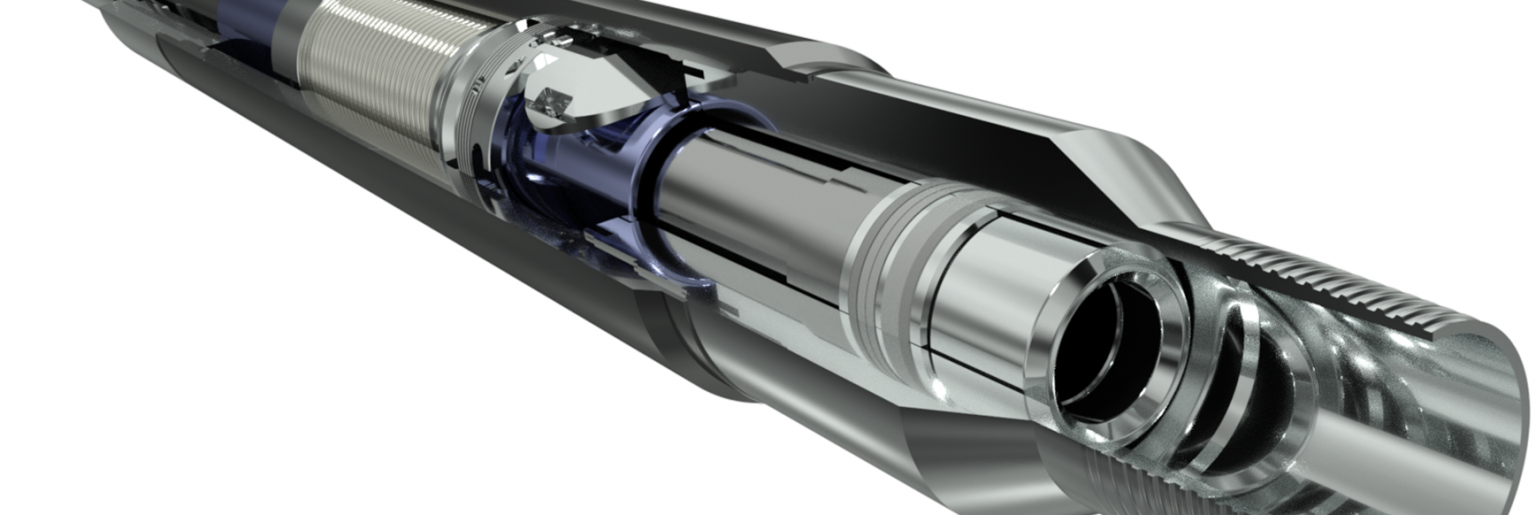

It is recommended, and in the majority of cases mandatory, to incorporate a secondary means of closure for all wells that are capable of natural flow to surface into the design of the completion string. The installation of a Subsurface Safety Valve accommodates this requirement by providing a positive emergency closure mechanism. Usually located below the surface Tubing Hanger, the valve can be either designed to close automatically when a predetermined flow condition occurs in the well or remotely operated on a fail-safe principle from surface.

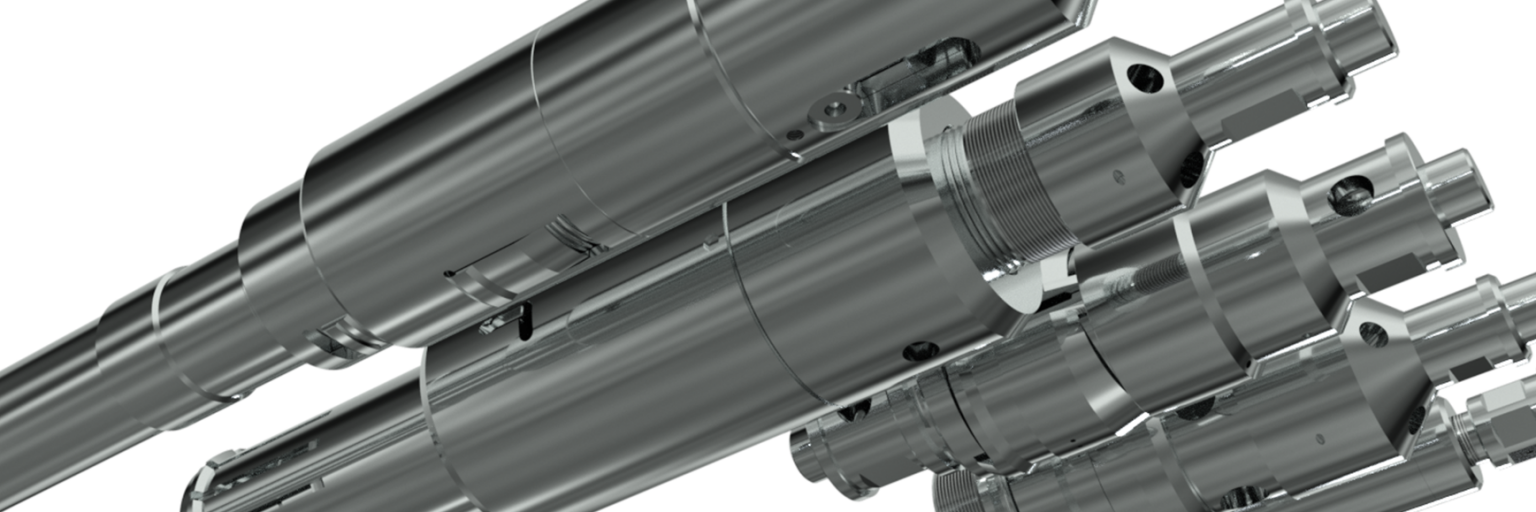

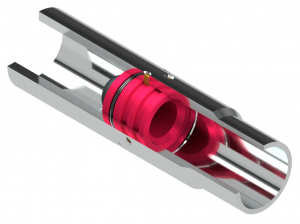

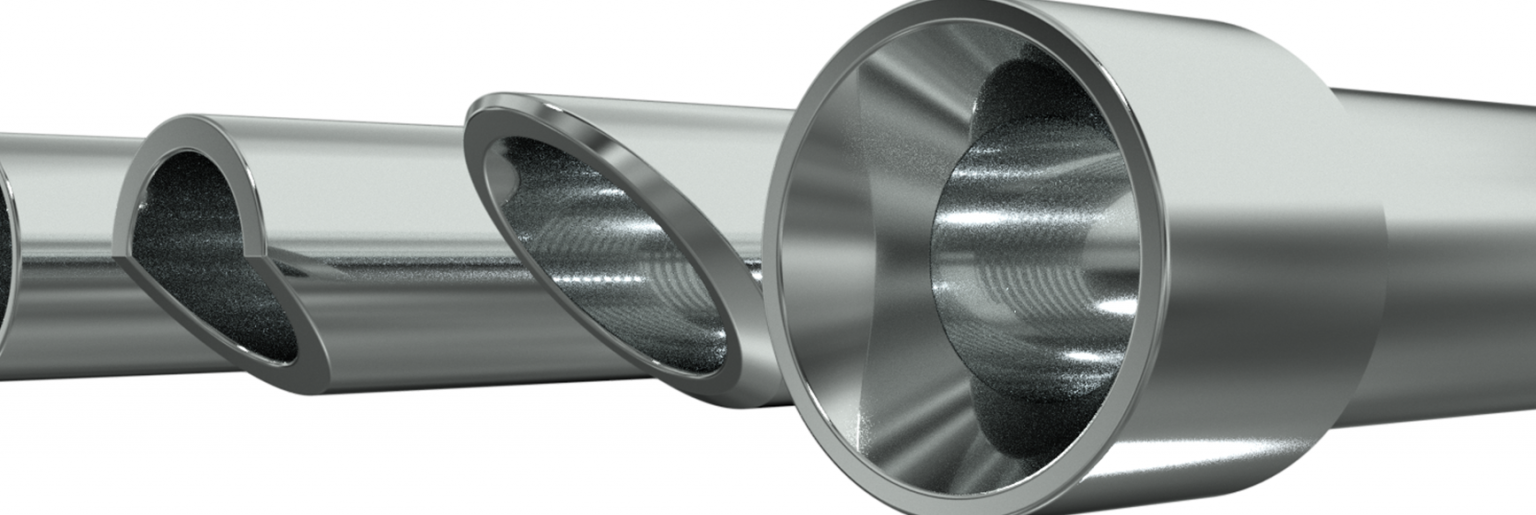

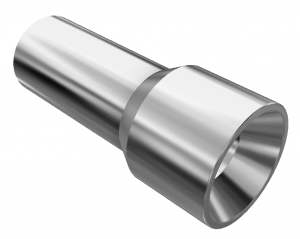

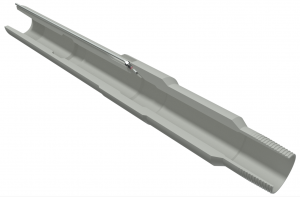

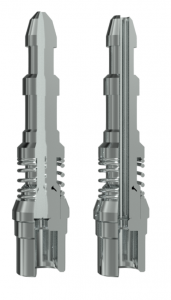

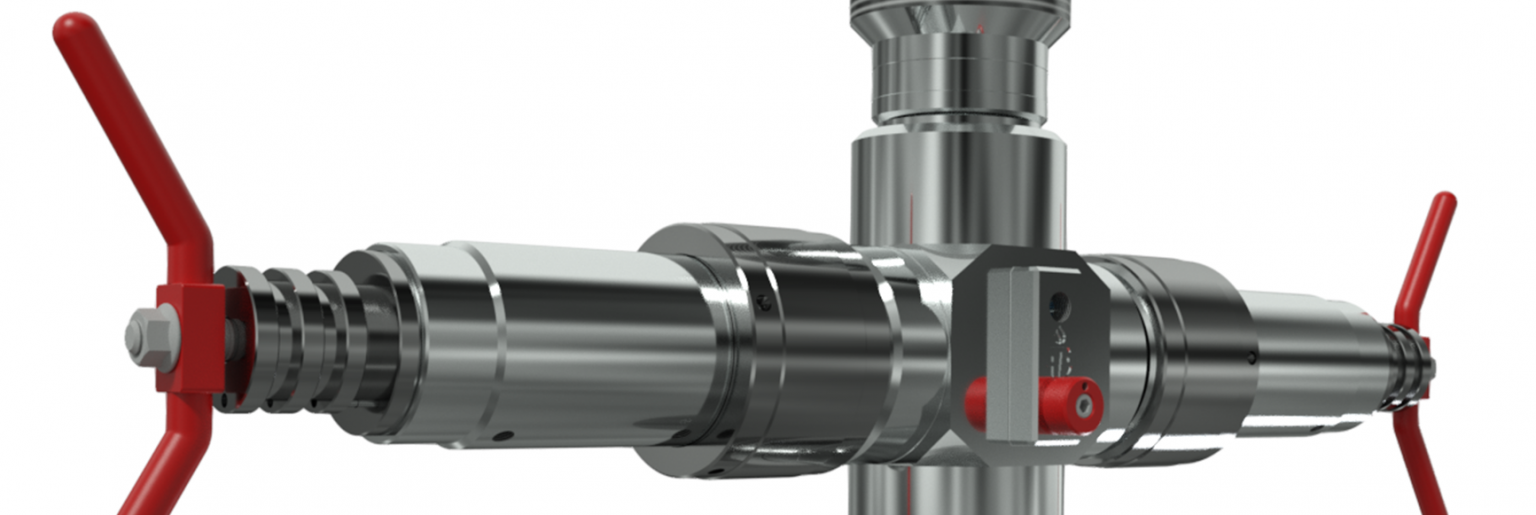

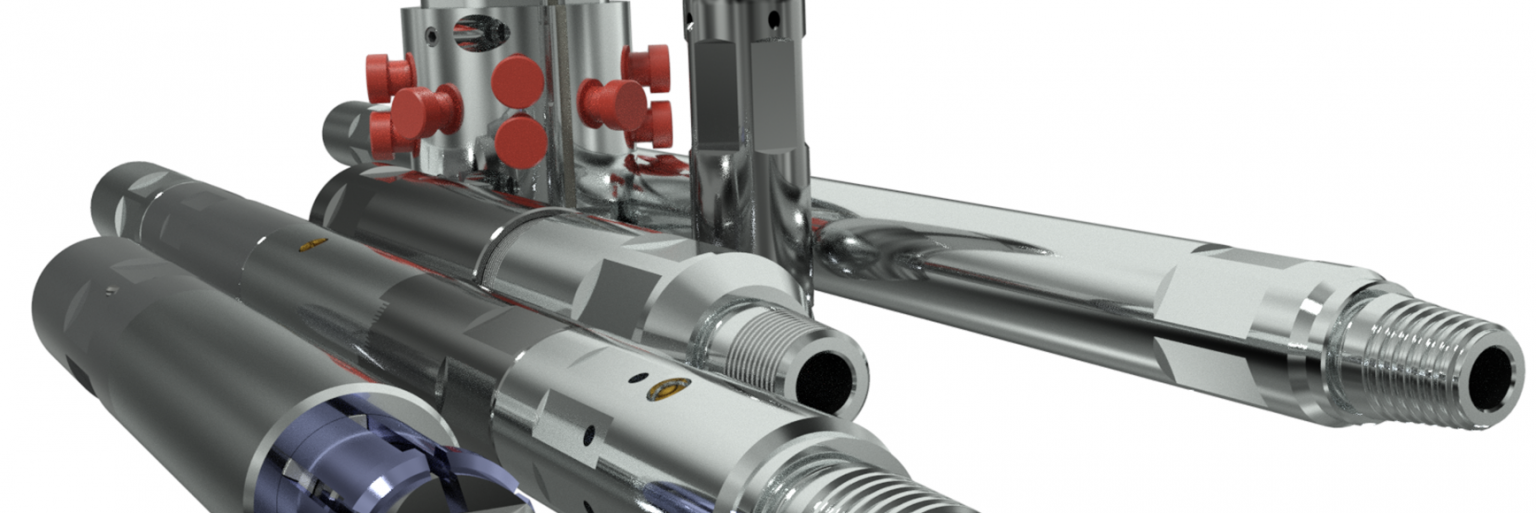

All of our Safety Valves incorporate the PTP Wedge Fitting connection as standard, to accept the Control Line and introduce communication between the valve and surface for successful operation. Our Safety Valves are designed and manufactured to provide positive subsurface control of oil and gas in, Production, Injection and Gas Storage wells both offshore and on land. PTP provide a range of Tubing Retrievable and Wireline Retrievable models supplied in 5,000 psi – 10,000 psi pressure ratings. We also offer a full and extensive family of accessories for all valves; including Lock Open Tools, Puncture Communication tools and Running/Pulling Prongs. Valves are available based on Metallurgic and Elastomeric requirements to suit virtually any well environment.